Michelin WISAMO wingsail: Decarbonisation of maritime transport

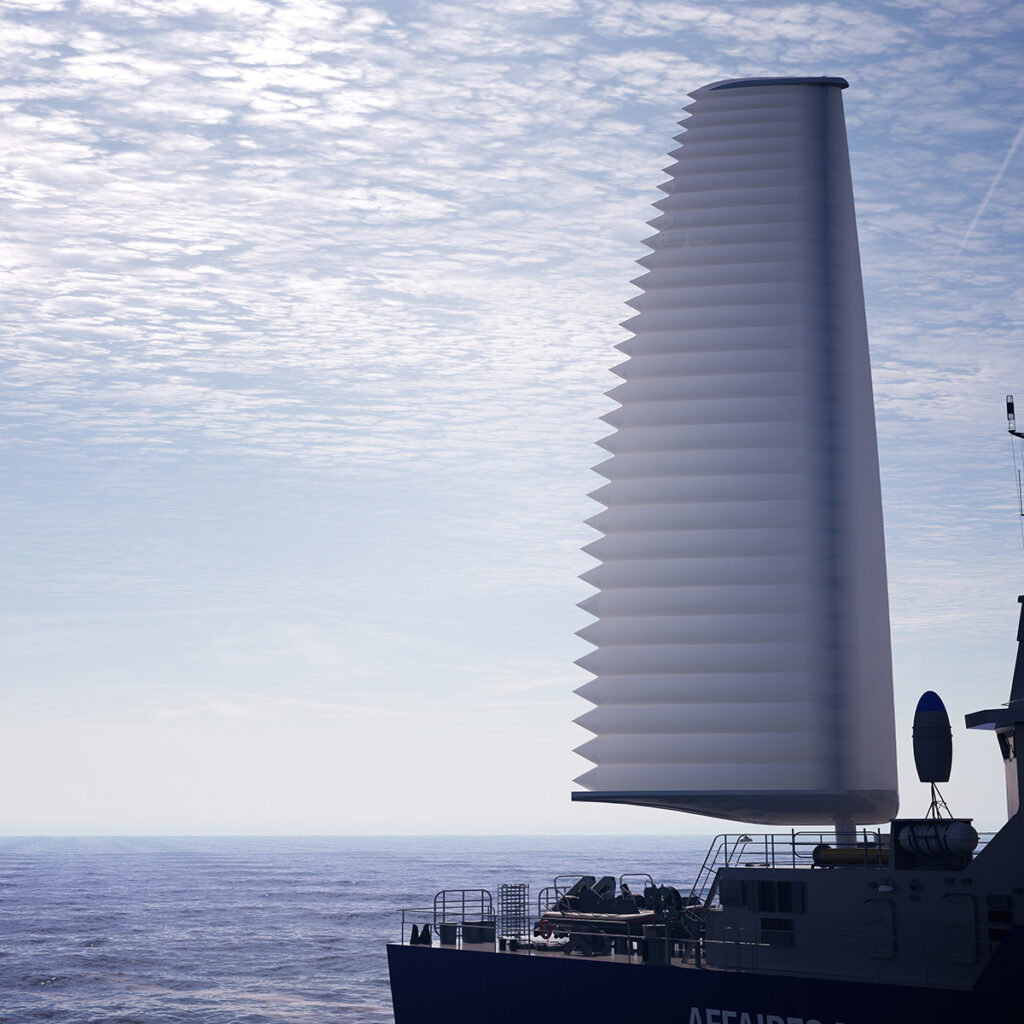

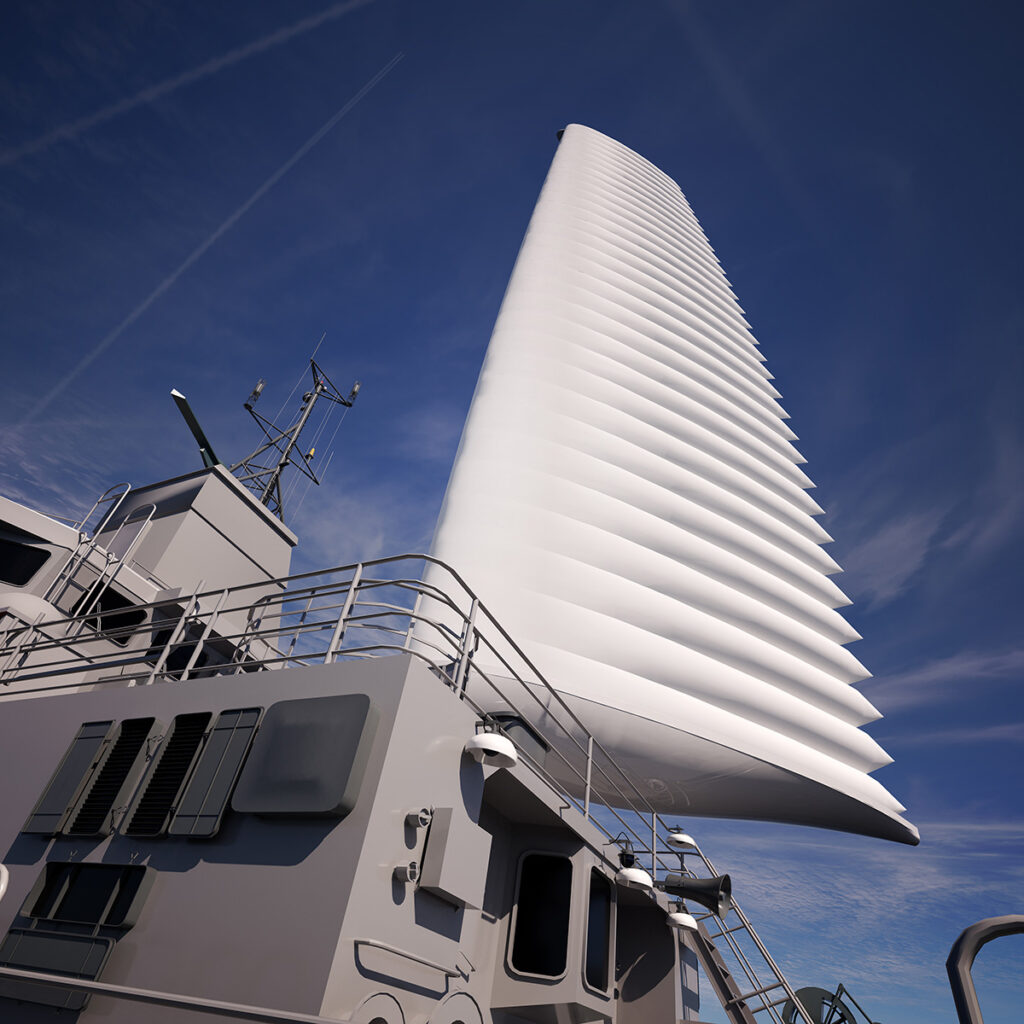

With the WISAMO (Wing Sail Mobility), Michelin is making an important contribution to resource-efficient maritime transport. Michelin has now received its first order and is equipping a new deep-sea patrol vessel with the sail system. The client is the French Directorate for Maritime Affairs, Fisheries and Aquaculture (DGAMPA).

The WISAMO wingsail, with a surface area of 170 m²/1,829 ft², will provide additional wind-assisted propulsion to complement the hybrid diesel-electric system. A fuel consumption reduction of approximately 15% is expected through optimisation of the design and the vessel’s operational profile.

Equipping a first ship is a significant step forward in the development of WISAMO, Michelin’s solution, which aims to support the decarbonisation of the maritime sector. This contract not only validates the relevance of our technological choices and the robustness of our solution but also reinforces Michelin’s pioneering spirit,” states Maude Portigliatti, Business Director of Polymer Composite Solutions and member of the Group’s Executive Committee.

Composite materials can be found in various areas of life

The WISAMO system is based on three key components: First a self-supporting telescopic mast that is fully retractable, allowing it to be deployed or stowed as needed. Second a durable lightweight fabric envelope that is inflated at low pressure to form a symmetrical wingsail profile. And third a fully automated control system that manages all sail functions (hoisting, lowering, adjusting, manoeuvering, reefing, and protective stowage according to environmental conditions), eliminating the need for additional crew workload. Its ease of use and fully retractable design make the WISAMO solution an all-rounder that can be adapted to numerous applications. WISAMO will be involved with the architectural firm and shipyard from the ship’s early design and development phases in 2025. It will also follow up on the onboard installation, scheduled for early 2027, until the full handover of the equipment. The Michelin teams will also be present for the sea trials, expected to take place at the end of that same year.

A “Made in France” collaboration

This new patrol vessel project — the successor to the Iris, which was designed nearly 40 years ago — is the result of a collaboration between three French companies: Mauric, the naval architecture firm responsible for the design; Socarenam, the shipyard in charge of construction; and Michelin, which will equip the vessel with an innovative WISAMO wind propulsion technology. In the coming years, WISAMO aims to develop a broad range of wingsails to support the decarbonisation of all types of ships, including sizeable vessels (large pleasure craft and work or cargo vessels, from 60 feet to 60 metres).

What are composite materials?

A composite material is the combination of two or more elements whose properties complement each other to form a product with superior performance. Tyres, by their construction, are ultra-complex products that contain up to 200 raw materials with very different, sometimes opposing properties which tend not to be associated. Together, however, they are capable of delivering what may seem like conflicting performance characteristics, from grip without excessive energy consumption, efficient braking combined with long life, and flexibility yet resilient. More specific examples of composite materials from Michelin are neoprene-coated fabrics, controlled-cooling firefighting clothing, industrial conveyor belts for the metal ore and agricultural harvesting industries as well as racecar body panels and wings, bicycle frames and sports equipment.